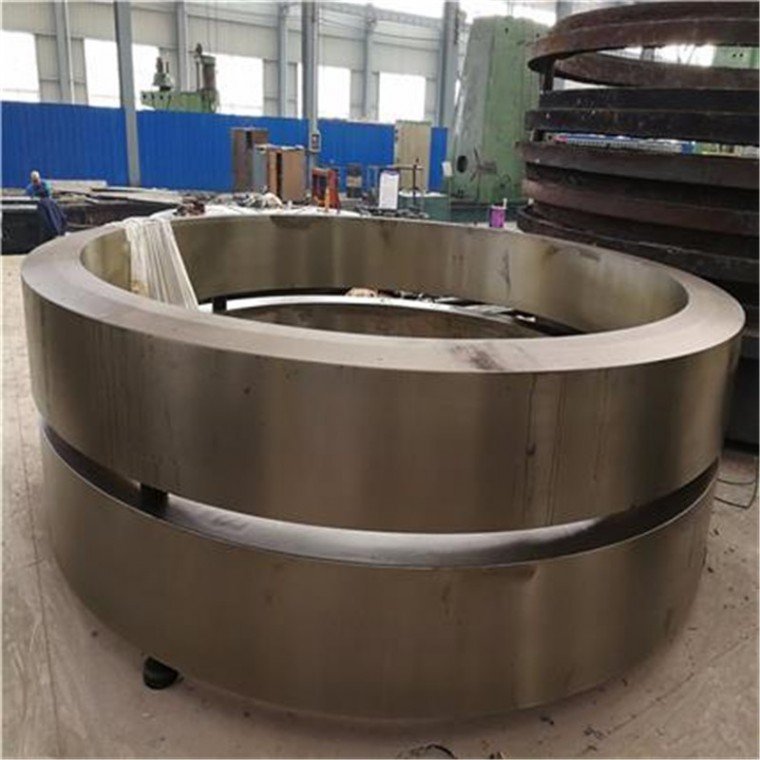

Rotary Kiln Tyre

Weight: 1-80Tons

Material: Steel ZG45, ZG42CrMo, etc

Application: cement, metallurgy, chemical, construction

Customizable: Yes, according to the drawing

Process introduction

Rotary kiln tyre is also called kiln rolling ring, rotary riding ring, which is the main part of rotary kiln. The function of the tyre is to transfer all the weight of the cylinder body to the supporting roller, and make the cylinder rotate smoothly on the roller, so the tyre should be powerful and durable enough. Meanwhile, it is the part to enhance radial stiffness of the rotary kiln shell, so it should be with excellent stiffness. We can produce all kinds of kiln tyre according to the drawings and sizes provided by customers.

According to the customer’s requirement, We chooses the appropriate wooden model for design and makes the CAE casting simulation before real casting. All the casting is made in strict accordance with the process of “wooden model—sand moulding—smelting & casting pouring—heat preservation—cleaning—heat treatment—rough finishing &fine finishing—package & delivery”, for high-quality tyre casting.

Precision Craftsmanship

The Tyre of rotary kilns is made of ZG45 and ZG42CrMo, which can guarantee its strength and toughness, and the function of support can be well performed. The kiln Tyre adopts the advanced double medium quenching process, which makes it with features of even casting, high quenching hardness and toughness. This makes the Kiln Tyre has good wear resistance and can be adapted to all kinds of bad working environment.

Advanced CNC machining is used to achieve exact dimensions and a flawless finish. Each kiln tyre undergoes comprehensive quality inspections, including ultrasonic testing and dimensional checks, to ensure there are no defects or inconsistencies.

Our Service

We are a cement plant Equipment and casting parts manufacturer and provider. Our company specializes in custom casting and forging components, offering tailored solutions based on customer requirements. We can select materials and processes according to client specifications and produce parts precisely to their drawings. With advanced manufacturing facilities and a team of experienced professionals, we ensure high-quality, precision-engineered products. Our commitment to innovation and rigorous quality control makes us a trusted partner for clients worldwide.

Product Details

Our Strengths

1. Professional technology

Econe Industrial as a high quality supplier of crusher and ball mill wear parts. We can provide you with various brands of crusher spare parts, also can customize and produce according to your working conditions. We provide Hammer crusher wear parts, Impact crusher wear parts, Jaw crusher wear parts, Ball mill wear parts, Vertical mill wear parts and Cone crusher wear parts.

2. Exceptional Production Capacity:

Equipped with state-of-the-art machinery and a skilled workforce, our factory boasts an impressive production capacity. We can fulfill large orders efficiently without compromising on quality.

3. Guaranteed Quality:

We are able to control dimensions according to tolerance casting; also have professional flaw detection equipment to ensure accurate control of the inherent quality of castings; sandblasting equipment is effectively assisted to improve surface quality.

4. Global Export Reach:

We take pride in our ability to serve customers worldwide. With a robust export network, our products reach various countries across continents, establishing our reputation as a trusted supplier on the global stage.

Related Products

We provide various accessories for ball mills, rotary kilns and crushers, which can be customized according to customer drawings.