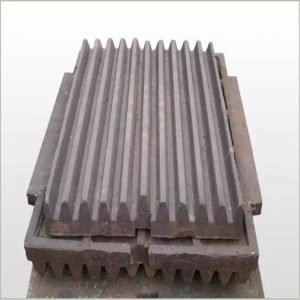

Crusher Jaw Plate

Weight: 10-800 kg

Material: manganese steel, Ni-hard, Ni-Cr alloyed cast iron.

Application: cement, metallurgy, mining, construction

Customizable: Yes, according to the drawing

Introduction

Jaw plates are designed to crush and fragment large rocks and other hard materials. They are mounted on the jaw crusher’s moving and stationary jaws, providing the necessary surface for the crushing action. The materials are fed into the crusher, and the jaw plates apply powerful compressive forces to break them down.

Our production process begins with selecting high-grade manganese steel, known for its excellent wear resistance and durability. The steel is then cast into jaw plate shapes using advanced casting techniques. Post-casting, the jaw plates undergo a series of heat treatments, including quenching and tempering, to enhance their hardness and toughness.

We adhere to strict international quality standards, employing continuous monitoring and improvement practices throughout the manufacturing process. Every jaw plate is subjected to comprehensive inspections to ensure it meets or exceeds industry benchmarks for performance and reliability.

Product Advantages

Our jaw plates offer several key advantages:

Exceptional Durability: Made from high-grade manganese steel, our jaw plates provide outstanding wear resistance, extending their service life.

Optimal Performance: Precision machining ensures a perfect fit and superior crushing efficiency.

Cost-Effective: The durability and efficiency of our jaw plates help reduce operational costs by minimizing downtime and maintenance needs.

Reliability: Our rigorous quality control processes ensure that each jaw plate delivers consistent and reliable performance under the most demanding conditions.

These features make our jaw plates a dependable and cost-effective choice for heavy-duty crushing applications, ensuring efficient and continuous operation in your crushing

Custom Service

We are a cement plant Equipment and casting parts manufacturer and provider. Our company specializes in custom casting and forging components, offering tailored solutions based on customer requirements. We can select materials and processes according to client specifications and produce parts precisely to their drawings. With advanced manufacturing facilities and a team of experienced professionals, we ensure high-quality, precision-engineered products. Our commitment to innovation and rigorous quality control makes us a trusted partner for clients worldwide.

Product Details

Our Strengths

1. Professional technology

Econe Industrial as a high quality supplier of crusher and ball mill wear parts. We can provide you with various brands of crusher spare parts, also can customize and produce according to your working conditions. We provide Hammer crusher wear parts, Impact crusher wear parts, Jaw crusher wear parts, Ball mill wear parts, Vertical mill wear parts and Cone crusher wear parts.

2. Exceptional Production Capacity:

Equipped with state-of-the-art machinery and a skilled workforce, our factory boasts an impressive production capacity. We can fulfill large orders efficiently without compromising on quality.

3. Guaranteed Quality:

We are able to control dimensions according to tolerance casting; also have professional flaw detection equipment to ensure accurate control of the inherent quality of castings; sandblasting equipment is effectively assisted to improve surface quality.

4. Global Export Reach:

We take pride in our ability to serve customers worldwide. With a robust export network, our products reach various countries across continents, establishing our reputation as a trusted supplier on the global stage.

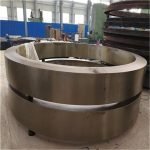

Related Products

We provide various accessories for ball mills, rotary kilns and crushers, which can be customized according to customer drawings.