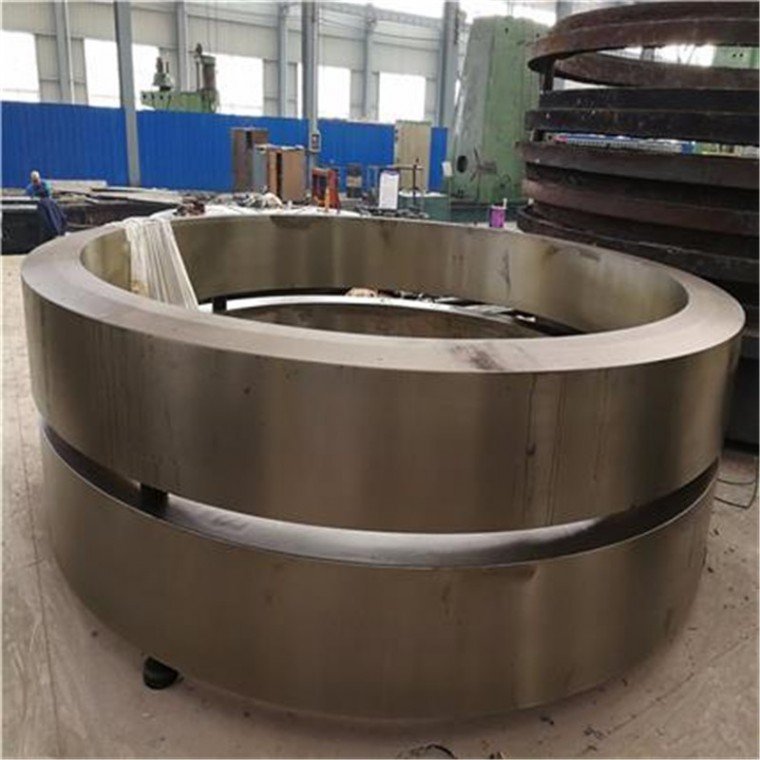

High Manganese Ball Mill Liners for Sale Long Service Life

Ball mill liners known as a grate liner is designed for discharge efficiency. It allows the discharge of ground materials via slots. Designs of grate liners depend on their drilling pattern, mill speed, grinding media diameter, media filling percentage, throughput and the presence of pebble.

Uses Of A Ball Mill Liners

The role of a ball mill liner is to give the mill shell and heads protection against wear and tear thus increasing their lifetime and creating optimal grinding efficiency. The design of a ball mill liner depends on the drilling pattern of the mill heads, the rpm speed of the mill, the maximum diameter of the grinding media and the percentage of media filling. In this way an optimum compromise can be achieved between grinding efficiency and the equipment´s lifetime. Continuous profile studies of the liners help monitor the situation so improvements can be made..

High-Quality Materials

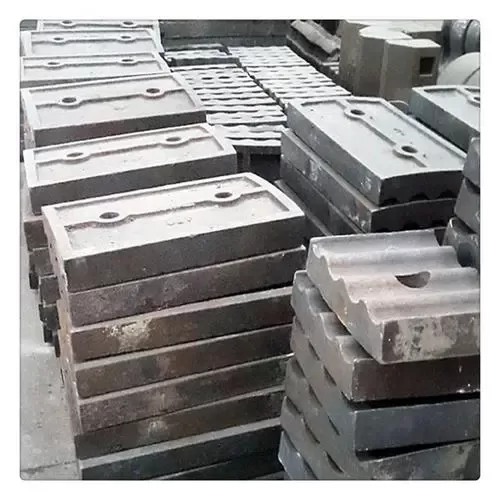

Made from premium alloy steel or wear-resistant cast iron, our liners offer exceptional impact resistance and wear properties.

Each liner undergoes rigorous testing to ensure consistent quality and remarkable durability.

Superior Durability:

The unique heat treatment process gives the liner a high surface hardness and excellent inner toughness, significantly extending its service life.

Even in high-impact, high-wear environments, the liner maintains outstanding wear resistance and durability.

The unique heat treatment process gives the liner a high surface hardness and excellent inner toughness, significantly extending its service life.

Even in high-impact, high-wear environments, the liner maintains outstanding wear resistance and durability.

Custom Service

We are a cement plant Equipment and casting parts manufacturer and provider. Our company specializes in custom casting and forging components, offering tailored solutions based on customer requirements. We can select materials and processes according to client specifications and produce parts precisely to their drawings. With advanced manufacturing facilities and a team of experienced professionals, we ensure high-quality, precision-engineered products. Our commitment to innovation and rigorous quality control makes us a trusted partner for clients worldwide.

Key Features:

High-Quality Materials: Crafted from alloy steel, high manganese steel, and rubber composite materials to ensure optimal strength and impact resistance.

Custom Designs: Tailored to fit specific mill dimensions and configurations, ensuring perfect alignment and secure installation.

Enhanced Grinding Efficiency: Strategically engineered profiles to improve the milling process and reduce energy consumption.

Extended Wear Life: Specially treated surfaces to minimize wear and extend the operational lifespan of the liners.

Easy Installation & Maintenance: Simplified installation procedures and easy-to-replace segments for minimal downtime.

Our Strengths

1. Professional technology

Econe Industrial as a high quality supplier of crusher and ball mill wear parts. We can provide you with various brands of crusher spare parts, also can customize and produce according to your working conditions. We provide Hammer crusher wear parts, Impact crusher wear parts, Jaw crusher wear parts, Ball mill wear parts, Vertical mill wear parts and Cone crusher wear parts.

2. Exceptional Production Capacity:

Equipped with state-of-the-art machinery and a skilled workforce, our factory boasts an impressive production capacity. We can fulfill large orders efficiently without compromising on quality.

3. Guaranteed Quality:

We are able to control dimensions according to tolerance casting; also have professional flaw detection equipment to ensure accurate control of the inherent quality of castings; sandblasting equipment is effectively assisted to improve surface quality.

4. Global Export Reach:

We take pride in our ability to serve customers worldwide. With a robust export network, our products reach various countries across continents, establishing our reputation as a trusted supplier on the global stage.

Related Products

We provide various accessories for ball mills, rotary kilns and crushers, which can be customized according to customer drawings.