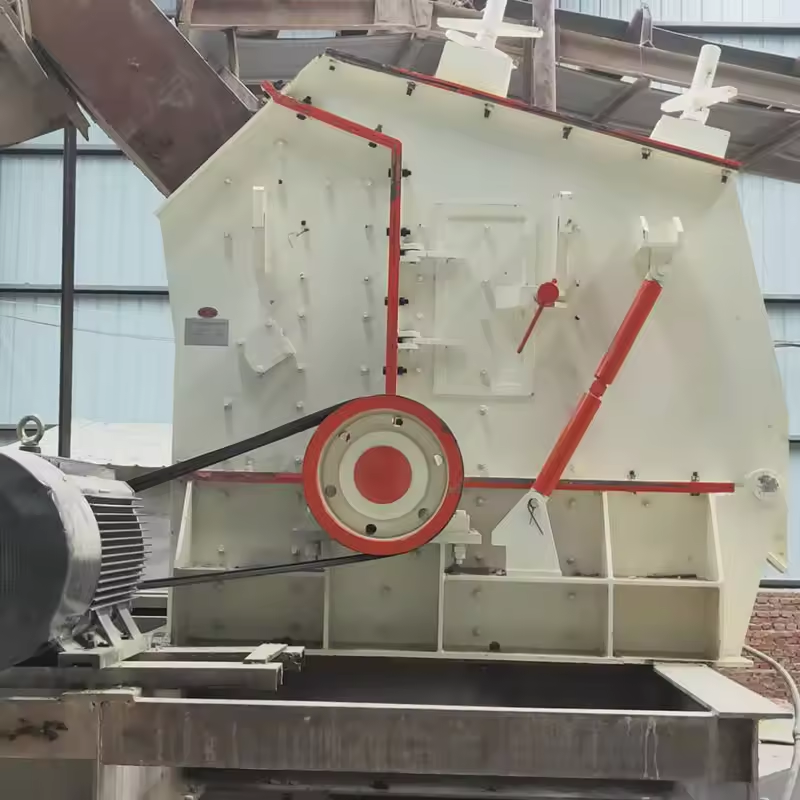

Impact Crusher

Capacity: 30-800t/h

Feeding Size: 300-800mm

Application: river gravel, granite, basalt, iron ore, limestone, quartz stone, coal gangue, dolomite, feldspar, calcite, talc, barite and building wastes, etc.

Introduction

Impact crusher is a processing equipment that uses impact energy to perform secondary and tertiary crushing of medium-hard brittle materials. It is often combined with a jaw crusher to form fixed, mobile, or track-mounted crushing production lines. It can be used in mine crushing, railway, highway, energy, cement, chemical, construction and other industries.

Currently, we have developed and produced PF Series Impact Crushers, CI Series Impact Crushers, HD German Type Impact Crushers, and Mobile Impact Crushers.

Outstanding Advantages

1. Superior production capacity: Large crushing ratio, the maximum output can reach 2,000 t/h.

2. Outstanding performance: The impact crusher has a large feed opening and high crushing cavity, suitable for large-sized materials, resulting in minimal stone powder in the final product.

3. Durable material: We use high-chrome blow bar that are resistant to impact and wear, with strong impact force.

4. Excellent particle shape: The gap between the impact plate and the hammer can be adjusted to effectively control the discharge particle size, resulting in uniform particle shape.

Technical Parameter

| Model | Specifications (mm) | Feed Opening (mm) | Max.Feeding Size (mm) | Capacity (t/h) | Power (kw) | Dimensions(L×W×H) (mm) |

| PF-1007 | Φ1000×700 | 400×730 | 300 | 30-70 | 4P 37-45 | 2330×1660×2300 |

| PF-1010 | Φ1000×1050 | 400×1080 | 350 | 50-90 | 4P 45-55 | 2370×1700×2390 |

| PF-1210 | Φ1250×1050 | 400×1080 | 350 | 70-130 | 6P 110 | 2680×2160×2800 |

| PF-1214 | Φ1250×1400 | 400×1430 | 350 | 80-180 | 6P 132 | 2650×2460×2800 |

| PF-1315 | Φ1320×1500 | 860×1520 | 500 | 100-280 | 6P 200 | 3180×2720×3120 |

| PF-1320 | Φ1300×2000 | 993×2000 | 500 | 140-380 | 6P 250 | 3220×3100×3120 |

| PF-1520 | Φ1500×2000 | 830×2040 | 700 | 200-550 | 4P 315-400 | 3959×3564×3330 |

| PF-1820 | Φ1800×2000 | 1260×2040 | 800 | 300-800 | 6P 630-710 | 4400×3866×4009 |

Prodect Details

Our impact crushers are engineered to provide maximum crushing efficiency. Featuring a high-speed rotor and a large crushing chamber, these machines deliver high reduction ratios and finely crushed material. The advanced design ensures optimal particle size distribution, which is critical for achieving high-quality end products. This superior crushing efficiency translates to higher throughput and optimized processing times, allowing your operations to run smoothly and productively.

Our Strengths

-

Exceptional Production Capacity:

- Equipped with state-of-the-art machinery and a skilled workforce, our factory boasts an impressive production capacity. We can fulfill large orders efficiently without compromising on quality.

-

Guaranteed Quality:

- Quality is at the forefront of everything we do. From the selection of raw materials to the final inspection, stringent quality control measures are implemented at every stage of production to ensure that our impact crusher meet the highest standards.

Global Export Reach:

- We take pride in our ability to serve customers worldwide. With a robust export network, our products reach various countries across continents, establishing our reputation as a trusted supplier on the global stage.

Customization Options:

- Recognizing that every client has unique requirements, we offer customization options to tailor our impact crusher to suit specific applications. Whether it’s size, material, or design specifications, we work closely with our clients to deliver personalized solutions.

Related Products

We provide various accessories for ball mills, rotary kilns and crushers, which can be customized according to customer drawings.

Ball Mill Liners

Girth Gear

Ball Mill Trunnion