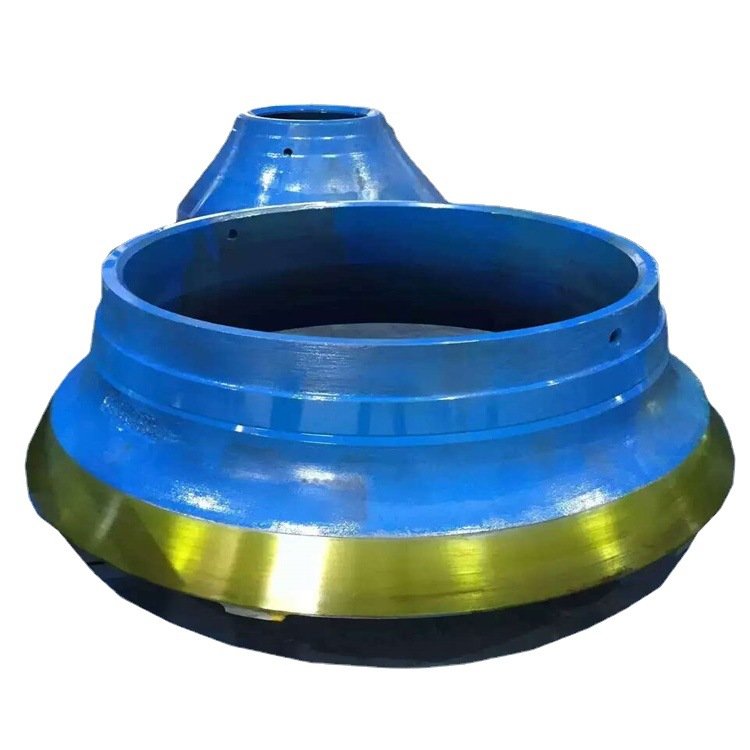

High-Quality Bowl Liners for Cone Crushers – Durable & Wear-Resistant

- Material: High Manganese Steel (Mn13, Mn18, Mn22), Chromium Alloys (Cr25, Cr27)

- Hardness: 50-60 HRC (depending on material specifications)

- Applications: Suitable for crushing granite, limestone, basalt, ore, and other hard materials

- Customizable: Bowl liners are available in various sizes and designs to fit different cone crusher models.

- Surface Finish: Smooth surface to ensure optimal contact with the crusher head for maximum crushing efficiency.

- MOQ: Contact us for bulk orders and pricing informatio

High-Quality Bowl Liners for Cone Crushers – Durable & Wear-Resistant

Introduction: Our High-Quality Bowl Liners for Cone Crushers are designed to provide superior wear protection and maximize the performance of your crushing operations. Crafted from premium materials such as high manganese steel and chromium alloys, these bowl liners deliver outstanding durability, ensuring your cone crushers operate at peak efficiency. Whether you are involved in mining, quarrying, or aggregate production, our bowl liners offer long-lasting protection for your crusher, reducing downtime and lowering maintenance costs.

Key Features of High-Quality Bowl Liners:

Durable Wear-Resistance: Constructed from high manganese steel and chromium alloys, our bowl liners are engineered to withstand the toughest crushing environments. They provide superior wear resistance, ensuring long service life and fewer replacements, which significantly reduces operational costs.

Maximized Crusher Performance: Designed to fit a wide range of cone crushers, our bowl liners enhance the overall performance of your crushing equipment. With optimized geometry, they offer consistent and efficient crushing, allowing you to achieve higher productivity and better material output.

High-Impact Resistance: Our wear-resistant bowl liners are specifically crafted for high-impact crushing applications. They excel in hard rock crushing, processing materials such as granite, basalt, limestone, and ore, ensuring long-term, reliable performance even under extreme conditions.

Customization Options: Available in various designs and sizes, our bowl liners are customizable to match the specifications of your cone crusher models. We ensure the perfect fit, allowing your equipment to run at maximum efficiency with minimal downtime.

Low Maintenance Costs: The superior wear characteristics of our bowl liners result in reduced maintenance needs. Fewer replacements and repairs mean lower total cost of ownership and less downtime for your crushing equipment.

Applications of High-Quality Bowl Liners:

Mining Industry: Our bowl liners are perfect for mining operations involving the crushing of hard rocks and minerals. They are designed to handle the wear and tear from processing ores and hard rocks such as gold, copper, and iron ore, providing reliable performance over extended periods.

Quarrying & Aggregate Production: Designed for use in quarry crushers, these bowl liners efficiently process granite, basalt, and other aggregate materials. Their superior wear resistance ensures that you get the most out of your cone crushers in high-volume crushing tasks.

Cement Manufacturing: Used in cement plants for the crushing of raw materials such as limestone and clay, our bowl liners reduce maintenance downtime and improve the efficiency of cement production processes.

Construction & Demolition: Ideal for construction sites where large quantities of material need to be crushed, our bowl liners provide the strength and durability needed for high-performance concrete recycling and demolition debris processing.

Product Details:

How We Work:

STEP-01

Consultation

We understand your needs and requirements to provide tailored solutions.

STEP-02

Manufacturing

Our skilled team utilizes state-of-the-art technology to produce high-quality cement equipment parts.

STEP-03

Delivery

We ensure prompt and secure delivery of your orders, anywhere in the world.

Why Choose Our High-Quality Bowl Liners?

Superior Material Quality: Made from high-grade manganese steel and chromium alloys, our bowl liners offer outstanding resistance to wear, cracks, and abrasions. These materials provide the ideal combination of hardness and toughness for cone crushers.

Efficient Crushing Operations: By reducing wear and tear on your crushing equipment, our bowl liners help maximize crusher uptime and minimize operating costs. This ensures your crushing operations are efficient, reliable, and cost-effective.

Long-Lasting Performance: The exceptional wear resistance of our high-quality bowl liners ensures they perform at their best over a long service life. Whether you’re dealing with hard rocks or abrasive materials, our liners can handle the job with ease.

Reduced Downtime: With optimized design and long-lasting materials, our bowl liners minimize downtime caused by part replacements. This helps you keep your operations running smoothly and efficiently, without frequent interruptions.

Environmentally Friendly: Our high-durability bowl liners are designed to last longer, which means fewer replacements and less waste. By improving your crusher’s efficiency and lifespan, we contribute to more sustainable operations.

Technical Specifications:

- Material: High Manganese Steel (Mn13, Mn18, Mn22), Chromium Alloys (Cr25, Cr27)

- Hardness: 50-60 HRC (depending on material specifications)

- Applications: Suitable for crushing granite, limestone, basalt, ore, and other hard materials

- Customizable: Bowl liners are available in various sizes and designs to fit different cone crusher models.

- Surface Finish: Smooth surface to ensure optimal contact with the crusher head for maximum crushing efficiency.

- MOQ: Contact us for bulk orders and pricing information

- Packaging: Custom packaging to ensure safe transport and delivery

Contact Us for a Quote or More Information:

If you’re looking for durable and wear-resistant bowl liners that maximize the efficiency of your cone crushers, contact us today. Our products are engineered to deliver exceptional performance in mining, quarrying, and cement production. Let us help you reduce downtime and improve your crushing operations. Get in touch now for more information and a personalized quote.

Conclusion:

Our High-Quality Bowl Liners for Cone Crushers are the ultimate solution for high-performance crushing. With superior wear resistance, customizable sizes, and low maintenance costs, they offer long-term value for industries such as mining, quarrying, and cement manufacturing. Invest in our bowl liners to enhance your crushing operations and ensure reliable performance.

Our Strengths

1. Professional technology

Econe Industrial as a high quality supplier of crusher and ball mill wear parts. We can provide you with various brands of crusher spare parts, also can customize and produce according to your working conditions. We provide Hammer crusher wear parts, Impact crusher wear parts, Jaw crusher wear parts, Ball mill wear parts, Vertical mill wear parts and Cone crusher wear parts.

2. Exceptional Production Capacity:

Equipped with state-of-the-art machinery and a skilled workforce, our factory boasts an impressive production capacity. We can fulfill large orders efficiently without compromising on quality.

3. Guaranteed Quality:

We are able to control dimensions according to tolerance casting; also have professional flaw detection equipment to ensure accurate control of the inherent quality of castings; sandblasting equipment is effectively assisted to improve surface quality.

4. Global Export Reach:

We take pride in our ability to serve customers worldwide. With a robust export network, our products reach various countries across continents, establishing our reputation as a trusted supplier on the global stage.

Recent Posts

Related Products

We provide various accessories for Jaw crusher, hammer crusher, impact crusher and cone crushers, which can be customized according to customer drawings.

Crusher Jaw Plate

Crusher Hammer

Cone Crusher concave and mentle